Professional Garment OEM/ODM Manufacturer

15+

Years Exp.

200k

Monthly Cap.

3k m²

Factory

30+

QC Staff

Your Trusted Manufacturing Partner In China

Darmax Garment Manufacturer brings your vision to life with 15+ years of expertise. From essential T-shirts to complex multi-process streetwear, we deliver exceptional quality across all categories. As an SGS-certified manufacturer, we ensure reliable quality control at every stage.

As your professional B2B manufacturing partner, we provide comprehensive one-stop services from fabric sourcing, production manufacturing, printing & embroidery processes to packaging and shipping.

Geographic Advantage

Fabric & trim markets located 2km

away for efficient sourcing.

Quick Sampling

Sample development in just 7-10 days with local supply chain advantages.

Eco-Friendly Priority

Prioritize the use of GRS, GOTS, and OEKO-TEX certified fabrics.

Strict Quality Control

30 QC inspectors, AQL standards,

4-stage quality control process.

Why Partner With Darmax?

Factory-Level Reliability

Stable production, strict QC, and a complete supply chain system rooted in China.

One-Stop Solution

Fabric sourcing, manufacturing, printing, embroidery, and packaging--all fully integrated.

Live Progress Tracking

Exclusive system link to view real-time production status for every step of your order. Transparency guaranteed.

Flexible Models

We support wholesale, private label, and custom development with flexible MOQs.

Fast Turnaround

Samples in 7-10 days. Bulk production in 20-30 days.

Sustainable Options

We source GRS, GOTS, and OEKO-TEX certified fabrics to help you meet global eco-standards.

Advanced Equipment & Skilled Workforce

Our 3,000 m² facility features state-of-the-art machinery for precision and efficiency, staffed by 150+ skilled workers and 30 QC professionals to maximize client value.

1,000,000+

Annual Production Capacity

- 3 Automatic Cutting Machines

- 6 Fabric Spreading Machines

- Fabric Inspection Machines

- 150+ Skilled Workers

- 30 Professional QC Staff

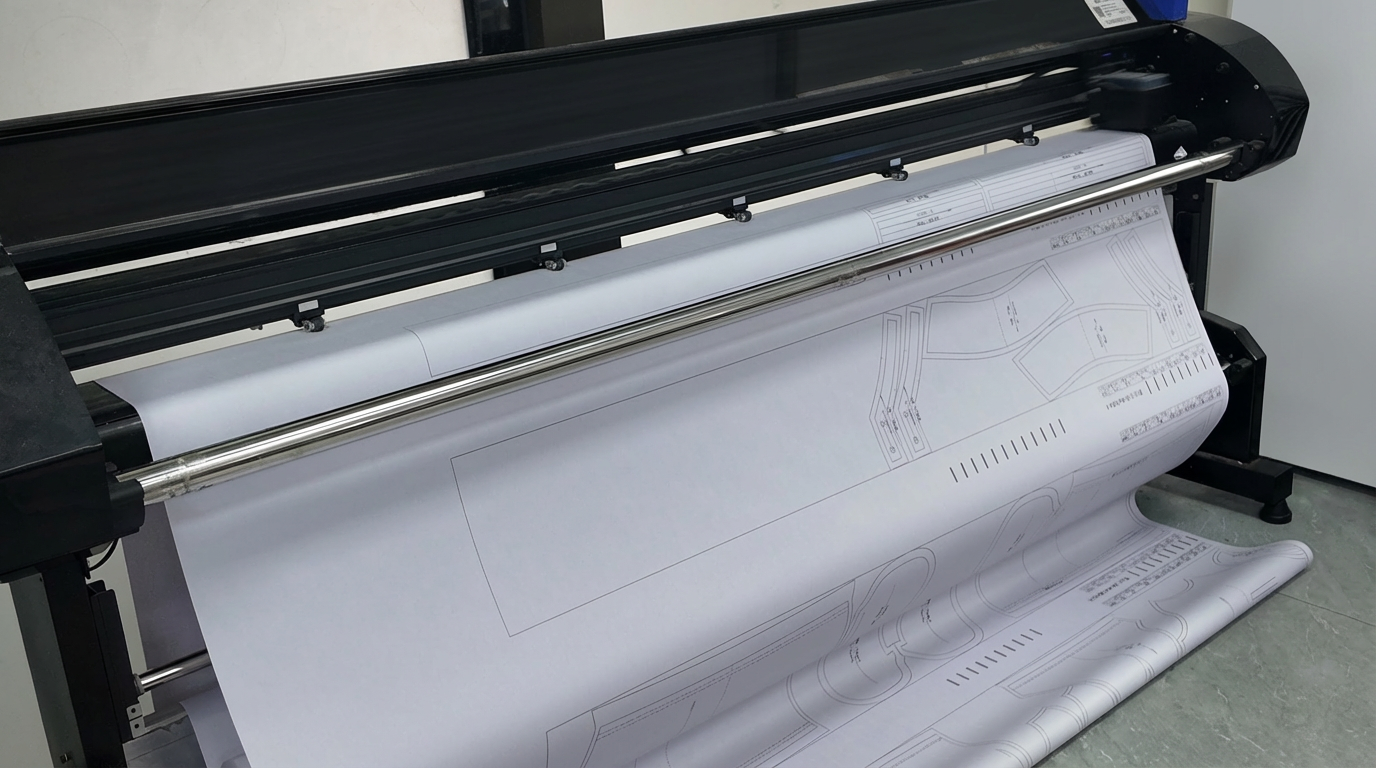

- 4 CAD Plotter

Production Capacity

High-Efficiency Automated Equipment

Fabric Spreading Machines

Keeps fabric layers smooth and aligned, minimizing manual errors.

Automatic Cutting Machines

Ensure precise, consistent cutting while greatly improving efficiency.

CAD Plotter

Advanced CAD layout optimizes fabric usage and reduces material waste.

Factory Environment

Cutting Department

Sewing Workshop

Quality Inspection Department

Packing Department

Manufacturing Workflow

From fabric inspection to final shipping, every step is monitored with strict quality control standards.

Fabric Inspection

Incoming Quality Control (IQC) and fabric pre-treatment to prevent shrinkage issues.

- Defect Detection

- Color Matching

- Steam Treatment

Fabric Cutting

Precision automatic cutting following approved patterns and markers.

- Automatic Cutting

- Pattern Accuracy

- Efficient Usage

Printing & Embroidery

Specialized decoration processes including screen printing and embroidery.

- Screen Printing

- Embroidery Work

- Heat Transfer

Sewing (IPQC)

Sewing with In-Process Quality Control at every station.

- Skilled Sewing

- Real-time QC

- Stitch Check

Ironing & Pressing

Professional steam pressing ensuring garment appearance and shape.

- Steam Pressing

- Shape Finishing

- Wrinkle Removal

Final QC (FQC)

Comprehensive final quality inspection before packaging.

- AQL Standards

- Measurements

- Appearance

Packaging

Professional packaging with custom labels, tags, and branded materials.

- Custom Labels

- Branded Packing

- Protection

Shipping (OQC)

Final outgoing quality control and secure shipping arrangement.

- Final Inspection

- Secure Shipping

- Tracking

Live Production Tracking

Transparency is our core value. Once cooperation is established, you receive a dedicated link to view real-time status updates for every production step, from cutting to shipping.

Trusted by Brands Globally

Darmax has been our manufacturing partner for 3 years. Their quality is consistent and the live tracking system saves us so much communication time.

Great for small batch production. We started with 100pcs and now order thousands. The team is very professional.

The sample turnaround was incredibly fast. They sourced the exact fabric I needed from the local market within a day.

Ready to start your

next collection?

Send us your tech pack or reference photos--we'll reply as soon as possible with a quote and sampling plan.